Answer:

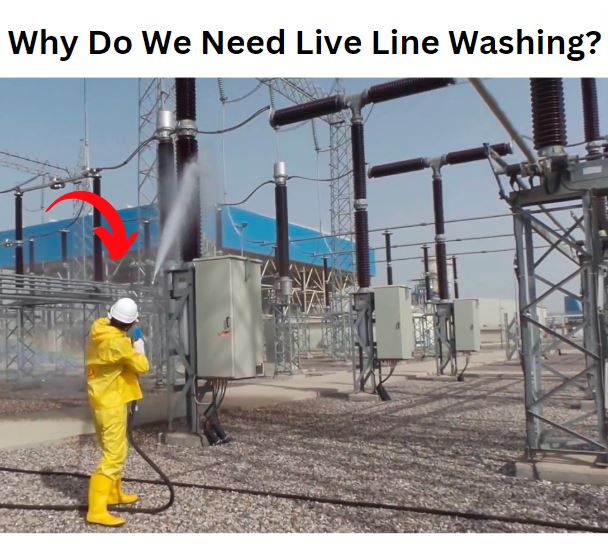

Live line washing is essential for maintaining electrical insulators on power lines. It removes accumulated pollutants, salt, and contaminants, preventing surface flashovers and ensuring uninterrupted power supply.

Reasoning:

Insulator Performance: Contaminants on insulators compromise their performance, leading to surface flashovers, disruptions, and potential equipment damage.

Preventing Power Outages: Regular live line washing reduces the risk of flashovers, ensuring a reliable power supply by preventing interruptions caused by contamination-induced faults.

Environmental Factors: Airborne pollutants, salt, and other debris can accumulate on insulators, particularly in coastal or industrial areas, necessitating cleaning to maintain insulation efficiency.

FAQs:

Q: What are surface flashovers?

A: Surface flashovers occur when contaminants on insulators create a conductive path, causing unintended electrical discharges.

Q: How does live line washing prevent outages?

A: By removing contaminants, live line washing mitigates the risk of surface flashovers, preventing faults and power disruptions.

Q: How often is live line washing conducted?

A: Frequency varies based on environmental conditions, with coastal and industrial areas often requiring more frequent cleaning.

Q: Can contaminants impact power quality?

A: Yes, contaminants on insulators can affect power quality by causing interruptions, voltage fluctuations, and equipment damage.

Q: Is live line washing applicable to all types of power lines?

A: Yes, live line washing is conducted on various types of power lines, including distribution and transmission lines.

Q: Can live line washing be done during power transmission?

A: Yes, specialized equipment allows live line washing to be performed without interrupting power transmission.

Q: Are there environmental benefits to live line washing?

A: Yes, removing contaminants prevents their deposition into the surrounding environment, contributing to overall environmental protection.

Q: Does live line washing improve the lifespan of insulators?

A: Yes, regular cleaning extends the lifespan of insulators by preventing surface damage and degradation caused by contaminants.

Q: Can live line washing be automated?

A: Yes, automated systems with robotic devices and specialized cleaning solutions are employed for efficient live line washing.

Q: Are there safety considerations during live line washing?

A: Safety protocols, including equipment grounding and proper training, are crucial to ensure the safety of personnel conducting live line washing.

Electrical Engineering World Wiring a Brighter Tomorrow!

Electrical Engineering World Wiring a Brighter Tomorrow!