Answer:

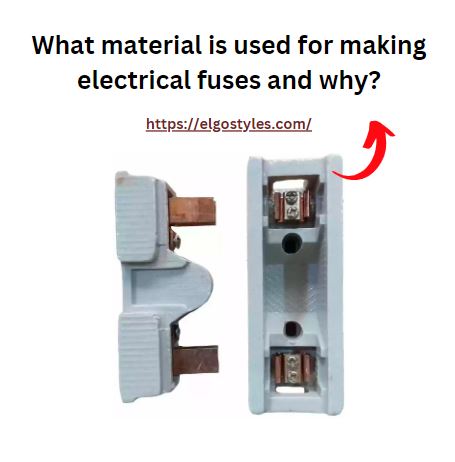

Electrical fuses are typically made from materials like glass, ceramic, or fiberglass-reinforced plastic. These materials are chosen for their ability to withstand high temperatures and provide insulation, ensuring safe operation. The fuse material must also have a predictable response to overcurrent conditions, quickly melting or breaking when current exceeds its rated capacity to prevent damage to the circuit.

Reasoning:

- Glass: Glass fuses are common due to their transparency, allowing easy visual inspection for damage.

- Ceramic: Ceramic fuses offer high heat resistance and mechanical strength, suitable for demanding applications.

- Fiberglass-reinforced Plastic: This material provides excellent electrical insulation and is durable in various environmental conditions.

- Thermal Conductivity: Fuses need materials with low thermal conductivity to concentrate heat at the fuse element, facilitating timely interruption of current flow.

- Predictable Melting Point: Material should melt or break predictably under overload conditions to quickly interrupt current flow and protect the circuit.

- Non-combustibility: The material must be non-combustible to prevent fire hazards during fuse operation.

- Cost-effectiveness: Materials chosen should strike a balance between performance and cost to ensure affordability.

- Manufacturability: The material should be easily molded or shaped into the desired fuse configuration during manufacturing.

- Compatibility: Materials must be compatible with the electrical properties of the circuit and other components.

- Regulatory Compliance: Fuse materials must meet relevant safety standards and regulations for electrical components.

FAQs:

What materials are commonly used in electrical fuses?

Glass, ceramic, and various metals are commonly used materials.

Why are these materials chosen for making fuses?

They can withstand high temperatures and interrupt the circuit effectively during overcurrent situations.

How does a fuse protect electrical circuits?

By melting or vaporizing when the current exceeds the rated value, thus breaking the circuit.

Can different fuse materials be used for different applications?

Yes, depending on the specific requirements of the application, different materials may be chosen.

What factors determine the choice of fuse material?

Current rating, voltage rating, environmental conditions, and the specific characteristics of the circuit.

Are there any drawbacks to using certain materials for fuses?

Some materials may have limitations in terms of their response time or ability to handle high currents.

How do ceramic fuses differ from glass fuses?

Ceramic fuses tend to have higher breaking capacities and are more robust compared to glass fuses.

Can metals alone be used for making fuses?

Yes, certain alloys or metals with specific properties can be used, but they might not offer the same performance as ceramic or glass fuses.

Do fuse materials affect the cost of manufacturing?

Yes, different materials have different costs associated with manufacturing, which can impact the overall cost of the fuse.

Are there any advancements in fuse materials being explored?

Yes, research is ongoing to develop materials with better performance characteristics, such as faster response times and higher breaking capacities.

Electrical Engineering World Wiring a Brighter Tomorrow!

Electrical Engineering World Wiring a Brighter Tomorrow!