Answer:

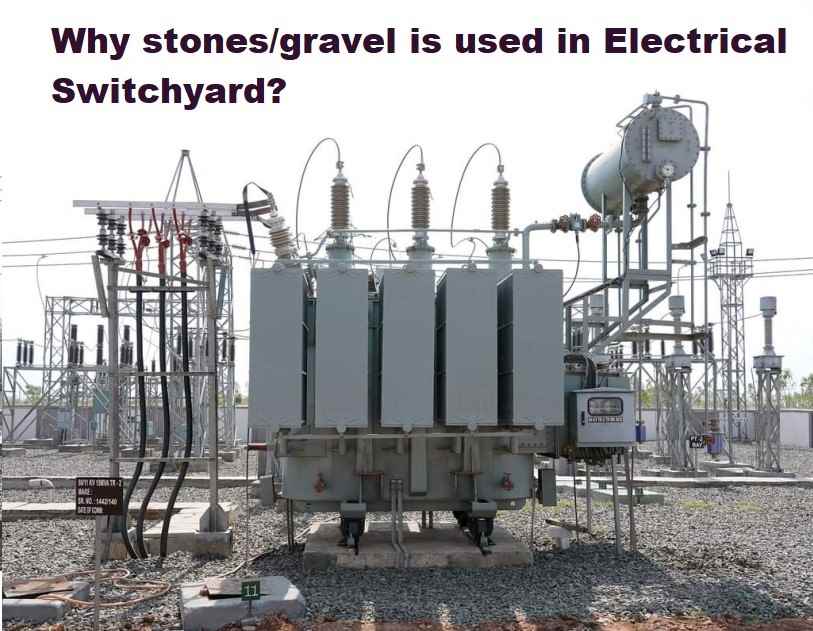

Stones or gravel are used in electrical switchyards primarily for their insulating properties and their ability to provide a stable, level surface for equipment and personnel.

Reasoning:

The complete reasoning behind this practice is multifaceted:

- Insulation: Stones/gravel act as a non-conductive layer between the ground and the electrical equipment, reducing the risk of electrical faults or short circuits caused by moisture or conductivity in the soil.

- Drainage: They help in proper drainage of rainwater, preventing pooling and reducing the risk of equipment damage due to water ingress.

- Stability: Stones/gravel create a stable foundation for heavy electrical equipment, ensuring that the equipment remains securely anchored, even in adverse weather conditions.

- Accessibility: They provide a solid surface for personnel to walk on, facilitating maintenance and inspection of the equipment without sinking into soft ground.

- Erosion Control: Gravel/stones help in preventing soil erosion around the equipment, maintaining the integrity of the switchyard structure over time.

- Maintenance: Using stones/gravel minimizes the need for frequent maintenance of the switchyard surface compared to grass or soil, reducing overall maintenance costs.

- Safety: The use of stones/gravel reduces the risk of fires caused by dry vegetation or combustible materials near electrical equipment.

- Visual Inspection: A gravel surface allows for easier visual inspection of the switchyard, enabling personnel to quickly identify any potential issues or hazards.

- Rodent Deterrent: Stones/gravel discourage burrowing animals like rodents, which can cause damage to underground cables and equipment.

- Environmental Impact: Compared to concrete or asphalt surfaces, using stones/gravel is more environmentally friendly as it allows for natural drainage and reduces heat retention.

FAQs:

Does using stones/gravel increase the lifespan of electrical equipment in a switchyard?

Yes, stones/gravel provide insulation and stability, thus prolonging the lifespan of equipment.

Can stones/gravel prevent electrical faults caused by moisture?

Yes, stones/gravel act as a non-conductive layer, reducing the risk of moisture-related faults.

Do stones/gravel require regular maintenance?

They require less maintenance compared to other surfaces, reducing overall maintenance costs.

Are there any safety benefits to using stones/gravel in a switchyard?

Yes, they reduce the risk of fires and provide a stable surface for personnel, enhancing safety.

Can stones/gravel help in preventing soil erosion around the equipment?

Yes, they serve as a barrier against erosion, maintaining the switchyard’s structural integrity.

Do stones/gravel contribute to environmental sustainability?

Yes, they allow for natural drainage and have a lower environmental impact compared to concrete or asphalt.

Can stones/gravel deter rodents from damaging underground cables?

Yes, they discourage burrowing animals, reducing the risk of cable damage.

Are there any disadvantages to using stones/gravel in a switchyard?

While rare, small stones/gravel may pose a tripping hazard if not properly managed.

Do stones/gravel provide better accessibility for maintenance personnel?

Yes, they create a solid surface for personnel to walk on, facilitating maintenance activities.

How do stones/gravel contribute to the stability of electrical equipment?

They provide a stable foundation, ensuring that equipment remains securely anchored, even in adverse weather conditions.

Electrical Engineering World Wiring a Brighter Tomorrow!

Electrical Engineering World Wiring a Brighter Tomorrow!