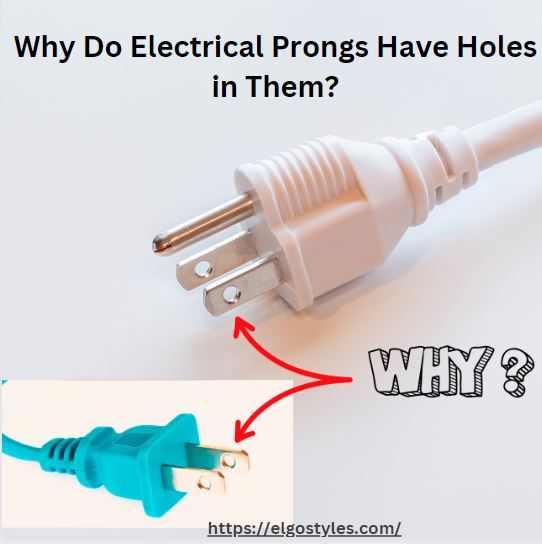

Answer:

Electrical prongs have holes in them to enhance safety by allowing the prongs to securely grip the outlet’s contacts and create a stable electrical connection.

Reasoning:

The holes in electrical prongs serve multiple purposes. Firstly, they allow for the insertion of small metal tabs within the outlet’s sockets. These tabs, when engaged with the prong holes, create a secure connection, preventing the prongs from slipping out accidentally. This design feature is crucial for maintaining a stable electrical connection and minimizing the risk of electrical hazards like short circuits or shocks.

Additionally, the holes aid in the alignment of the prongs within the outlet, ensuring that the live and neutral prongs are correctly oriented. This alignment is essential for proper electrical flow and device functionality.

Moreover, the holes also facilitate the insertion of grounding prongs found in three-pronged plugs. Grounding prongs provide an additional safety measure by redirecting excess electrical current safely into the ground, protecting both the device and the user from potential electrical faults or surges.

FAQs:

Q: Why do electrical prongs have holes?

A: The holes aid in creating a secure connection with the outlet’s contacts for safety.

Q: Do all electrical plugs have holes in their prongs?

A: No, not all plugs have holes, but most modern designs incorporate them for safety reasons.

Q: How do the holes in electrical prongs enhance safety?

A: They help prevent accidental slippage, ensure proper alignment, and facilitate grounding for added safety.

Q: Are there variations in the sizes of prong holes?

A: Yes, prong holes can vary in size depending on the type of plug and its intended usage.

Q: Can electrical prongs function effectively without holes?

A: While it’s possible, the absence of holes may compromise safety and stability.

Q: Are there international standards regarding prong hole dimensions?

A: Yes, many countries have standards specifying the size and placement of prong holes for consistency and safety.

Q: What materials are typically used to make electrical prongs?

A: Electrical prongs are commonly made of metals like brass or steel for conductivity and durability.

Q: Do the holes in prongs affect electrical conductivity?

A: No, the holes are designed not to impede conductivity but rather to enhance safety and stability.

Q: Can the holes in electrical prongs wear out over time?

A: With prolonged use, the holes may experience wear, but proper maintenance can mitigate this issue.

Q: Are there alternative designs to prong holes for securing electrical connections?

A: Yes, some plugs use other mechanisms such as clips or clamps, but holes remain a widely adopted standard for safety and reliability.

Electrical Engineering World Wiring a Brighter Tomorrow!

Electrical Engineering World Wiring a Brighter Tomorrow!