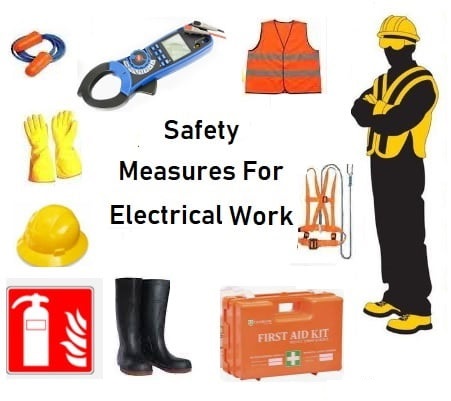

Safety Measures For Electrical Work

Introduction

Safety measures are crucial in electrical work to prevent injuries and fatalities caused by electrical hazards. Electrical work involves the use of electrical energy, which can be hazardous and potentially lethal if not handled properly. Therefore, following safety measures is critical to reduce the risk of electrical accidents.

The risks associated with electrical work include electrical shock, burns, and electrocution. These hazards can result from contact with electrical current, exposure to electrical arcs or flashes, and improper use of electrical equipment.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is essential in electrical work to protect workers from electrical hazards. PPE includes a variety of items such as gloves, eye protection, hard hats, and protective clothing.

Gloves provide protection against electrical shock and burns. They must be made of appropriate materials to withstand the voltage and current level of the electrical equipment being used.

Eye protection is essential to protect the eyes from electrical arcs and flashes. Safety glasses or goggles with side shields should be worn while working with electrical equipment.

Hard hats protect the head from impact and penetration. In addition, they can also protect against electrical shocks and burns if they are made of non-conductive materials.

Wearing PPE is critical to prevent electrical injuries. It is essential to choose the appropriate PPE for the specific electrical hazard and ensure that it is in good condition before using it. PPE should be worn at all times when working with electrical equipment, and workers should be trained on its proper use and maintenance.

In conclusion, personal protective equipment plays a crucial role in ensuring electrical safety. Workers must be trained in the appropriate use and maintenance of PPE and must wear it consistently to reduce the risk of electrical injuries.

Lockout/Tagout procedures

- Lockout/tagout procedures are used to prevent the unexpected start-up of machinery or equipment that could cause harm to employees working on it.

- This involves turning off the power source, disconnecting or isolating the machinery or equipment from the power source, and then locking or tagging the energy source to prevent it from being turned back on.

- Lockout/tagout procedures are important in preventing electrical injuries because they ensure that the machinery or equipment is completely shut down and cannot accidentally be turned back on while employees are working on it.

Electrical equipment safety

- Proper maintenance and inspection of electrical equipment is important to ensure that it is safe to use and does not pose a risk of electrical injury to employees.

- Electrical equipment should be inspected regularly for any signs of wear and tear, damage, or malfunction.

- Any electrical equipment that is found to be faulty or damaged should be repaired or replaced immediately.

- It is also important to use equipment that meets safety standards, such as those set by the Occupational Safety and Health Administration (OSHA) or other regulatory bodies. This ensures that the equipment has been tested and meets safety standards to prevent electrical injuries.

Safe work practices

- Safe work practices are essential for preventing electrical injuries in the workplace.

- Employees should keep work areas clean and dry, and ensure that there are no potential electrical hazards present, such as exposed wiring.

- Proper tools and equipment should be used when working with electricity, including insulated gloves, tools, and equipment.

- Employees should also be trained on safe work practices and should follow them to prevent electrical injuries.

Emergency procedures

- In the event of an electrical accident, it is important to have emergency procedures in place to prevent serious injuries.

- Employees should know how to respond in case of an electrical accident, including calling for emergency medical services and providing first aid.

- Electrical panels should be clearly marked and easily accessible in case of an emergency.

- Employees should also be trained on how to use fire extinguishers to prevent fires caused by electrical accidents.

- Regular emergency drills should be conducted to ensure that all employees are prepared to respond in case of an electrical emergency.

FAQs

What are the electrical safety measures?

Electrical safety measures include wearing personal protective equipment, following lockout/tagout procedures, properly maintaining and inspecting electrical equipment, practicing safe work habits, and being prepared for emergency situations.

What are the 5 electrical safety rules?

The 5 electrical safety rules are:

- Always assume that a circuit is live.

- Make sure that the power is turned off before working on any electrical equipment or circuits.

- Use insulated tools and equipment when working with electricity.

- Avoid working near water or in wet conditions when using electrical equipment.

- Never attempt to work on electrical equipment or circuits without proper training and authorization.

What are the 10 electrical safety rules?

While there are many safety rules related to electrical work, here are 10 commonly referenced ones:

- Always follow proper lockout/tagout procedures.

- Never touch electrical equipment or circuits with wet hands or while standing in water.

- Never use damaged or faulty electrical equipment.

- Use the right tool for the job and use it correctly.

- Keep electrical equipment clean and dry.

- Do not overload electrical circuits or extension cords.

- Use personal protective equipment, such as insulated gloves and safety glasses.

- Keep electrical panels and breakers labeled and easily accessible.

- Only trained and authorized personnel should work on electrical equipment or circuits.

- Always follow emergency procedures in case of an electrical accident.

What is the most important rule of electrical safety?

One of the most important rules of electrical safety is to always assume that a circuit is live. This means that you should treat all electrical equipment and circuits as if they are energized, and take appropriate safety measures, such as wearing personal protective equipment and following lockout/tagout procedures.

What are 3 electrical safety tips?

Here are three electrical safety tips:

- Always turn off the power before working on any electrical equipment or circuits.

- Never touch electrical equipment with wet hands or while standing in water.

- Always use insulated tools and equipment when working with electricity.

What are 10 safety rules in a workshop?

While specific safety rules may vary depending on the type of workshop, here are 10 commonly referenced ones:

- Wear appropriate personal protective equipment.

- Keep the work area clean and organized.

- Use tools and equipment properly and safely.

- Only use equipment that is in good condition and properly maintained.

- Always follow lockout/tagout procedures when working on machinery or equipment.

- Follow proper procedures when handling chemicals and hazardous materials.

- Do not perform any work that you are not trained and authorized to do.

- Keep fire extinguishers and other emergency equipment accessible.

- Know the location of emergency exits and be prepared to evacuate if necessary.

- Always follow emergency procedures in case of an accident or emergency.

What is safety in electrical workshop?

Safety in an electrical workshop involves taking appropriate measures to prevent electrical accidents and injuries, such as following lockout/tagout procedures, properly maintaining and inspecting electrical equipment, and using personal protective equipment. It also involves being prepared for emergency situations and following proper emergency procedures.

What is the golden rule of safety?

The golden rule of safety is to always put safety first. This means that when performing any task, you should consider the potential risks and take appropriate safety measures to prevent accidents and injuries. It also means that you should look out for the safety of others and report any unsafe conditions or behaviors.

Conclusion

In conclusion, safety measures are critical for preventing electrical injuries in the workplace. Personal protective equipment, lockout/tagout procedures, proper maintenance and inspection of electrical equipment, safe work practices, and emergency procedures are all important components of a comprehensive electrical safety program. By following these measures and guidelines, employees can reduce the risk of electrical injuries and ensure a safe working environment.

Electrical Engineering World Wiring a Brighter Tomorrow!

Electrical Engineering World Wiring a Brighter Tomorrow!